Our avid readers tend to look at microelectronics made using leading edge process technologies, which in case of Intel means usage of High-NA extreme ultraviolet (EUV) lithography a couple of years down the road. But the vast majority of chips that we are going to use in the next couple of years will be made using Low-NA EUV litho tools. This is why the latest announcement from ASML is particularly notable.

As spotted by Computerbase, ASML this week has delivered its first updated Twinscan NXE:3800E lithography machine for fab installation. The latest iteration of the company’s line of 0.33 numerical aperture (Low-NA) lithography scanners, the NXE:3800E is aimed at making chips on 2nm and 3nm-class technologies.

Chipmakers have a need for speed! The first TWINSCAN NXE:3800E is now being installed in a chip fab. 🔧

With its new wafer stages, the system will deliver leading edge productivity for printing advanced chips. We’re pushing lithography to new limits. 💪 pic.twitter.com/y5hJg5Tdot

— ASML (@ASMLcompany) March 12, 2024

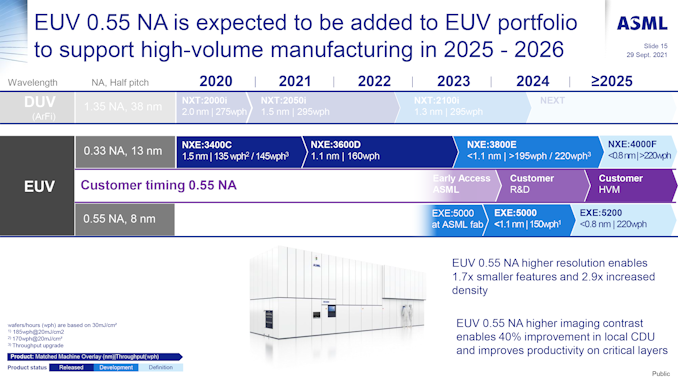

ASML has not published the full details on the capabilities of the machine, but previous roadmaps from the company have indicated that the updated 3800E would offer both improved wafer throughput and increased wafer alignment precision – what ASML refers to as “matched-machine overlay”. Based on that roadmap, ASML is expecting to crack 200 wafers per hour with their fifth-generation low-NA EUV scanner, which would mark a significant milestone for the technology, as one of the drawbacks of EUV lithography since the beginning has been its lower throughput rate compared to today’s extremely well-researched and tuned deep UV (DUV) machines.

For ASML’s logic and memory fab customers – a list these days that is only around half a dozen companies in total – the updated scanner will help these foundries continue to improve and expand their production of leading-edge chips. Even with major fabs in the midst of scaling-up their operations with additional facilities, improving throughput at existing facilities remains an important factor in meeting capacity demands, as well as bringing down production costs (or at least, keeping them in check).

Though as EUV scanners don’t come cheap – a typical scanner costs some $180 million and the Twinscan NXE:3800E will likely cost more – it’ll take a while to fully amortize these machines. In the meantime, shipping a faster generation of EUV scanners will have significant financial implications for ASML, who is already enjoys the status (and criticism) that comes from being the sole supplier of such a critical tool.

Following the 3800E, ASML has at least one more generation of low-NA EUV scanners in the works, with the development of the Twinscan NXE:4000F. That’s expected to be released around 2026.

Source: ASML (via Computerbase)