Not your casual CineD title but an important topic in our opinion. As reported by the British AAIB (Air Accidents Investigation Branch), an Airbus A321 suffered severe Airbus window damage during flight and performed an emergency landing shortly after takeoff. Two windows flew off and one dislodged. Later inspection revealed the reason – exposure to intense power lights ahead of the flight. The intense lighting melted some key components and caused the incident. Luckily no one was injured.

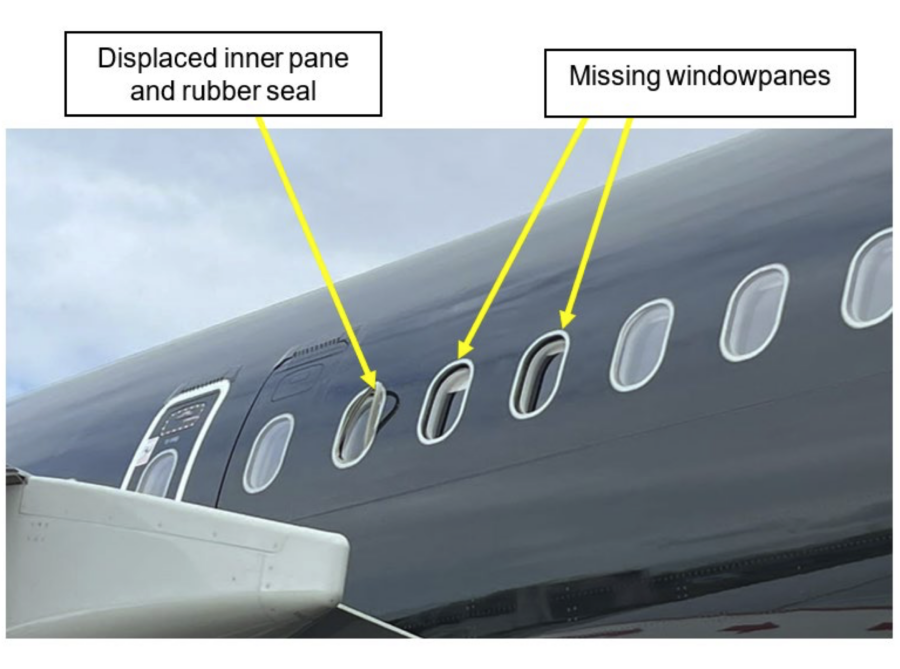

The incident occurred on the 4th of October 2023, at London Stansted Airport as a commercial Airbus A321 took to the sky. On board the Airbus were eleven crew members and nine passengers. As the aircraft gained altitude, the passengers reported unusually low temperatures. Quick assessment pointed to a missing window and the plane turned around for an emergency landing. Ground inspection reported airbus window damage – two missing windows and one dislodged.

Airbus window damage – the weakest link

The windows on an airplane have been a long-time weak spot in the aviation industry. The fact that they are transparent dictates that specific materials won’t always align with aircraft-grade alloys. Among the most famous cases involved the world’s first jet airliner, the British de Havilland Comet.

First-gen risks

As a tech-savvy audience, CineD readers are well aware of at least some instances involving various malfunctions in first-gen products. Innovation comes with a plethora of new challenges, and some are not as apparent as others. In our industry, a mere firmware update would solve most issues. In rare cases, a recall will take place. Regarding the aviation industry, the stakes are much higher. The Comet’s new technology was limited by outdated engineering methods. Its windows, much like every other window of any other aircraft, were rectangular. Unlike airlines that came before the Comet, it flew at an altitude of 40,000 feet. Maintaining a pressurized cabin at such an altitude meant more contraction and expansion of the fuselage. Since windows don’t respond the same way as the alloy around them, the fuselage becomes compromised as tiny cracks appear and grow. This phenomenon highlighted the dangers of metal fatigue in pressurized aircraft and led to the adoption of oval-shaped windows on modern airliners.

Back to the A321

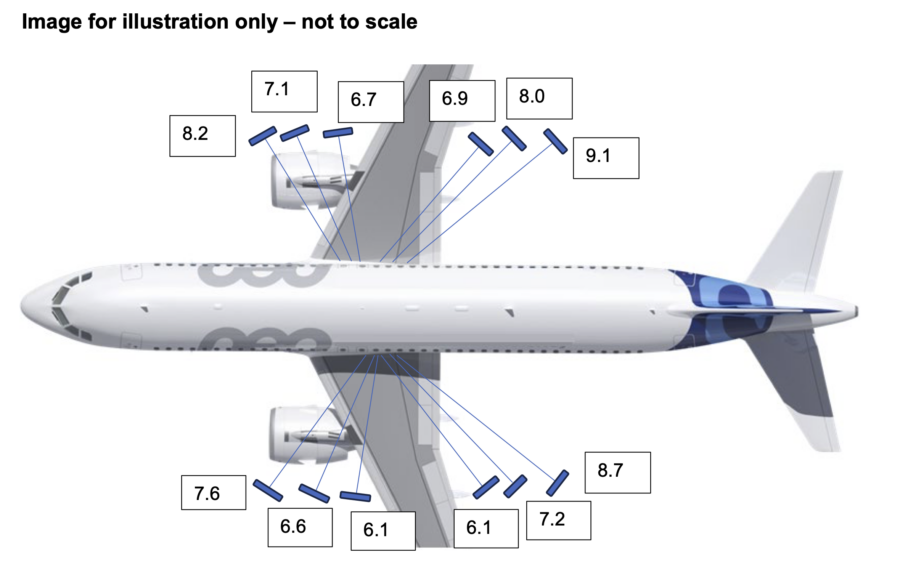

As the investigation went on, an important detail was revealed: The A321 had been used for an undisclosed filming activity. Twelve high-capacity floodlights, six on each side, had been aimed at the middle of the craft.

The lighting gear was identified as the 12,000 Watt FILMGEAR Maxibrute 12. Each of them reaches a max surface temperature of 200 degrees Celsius. While the minimal working distance is specified as 10m, it appears the fixtures were positioned much closer, resulting in thermal damage and distortion over approximately five hours of filming.

An important lesson

This incident highlights our responsibility as filmmakers. As we work with powerful lighting fixtures, heavy rigs, tall stands, etc., we must take great care regarding safety regulations and use a decent amount of common sense. Accidents might happen, but it’s our responsibility to minimize them as much as we can.

Have you ever worked on a set where a safety issue wasn’t recognized? What do you think about the potential for accidents on set? Let us know in the comments below.